China Supplier Waterproof 115V Ec 250mm Commercial Ventilation Fan for FFU

Description

Basic Info

| Material | Metal |

| Blade Material | Plastic |

| Type | Axial Fan |

| Electric Current Type | AC |

| Mounting | Free Standing |

| Certification | RoHS, CE |

| Name | Ec Axia Flow Fan |

| Category | Ventilation Equipment |

| Motor Type | Ec Brushless External Rotor Motor |

| Bearing Type | Ball Bearing |

| Fan Feature | 0~10VDC/PWM Speed Control, Tach Output |

| Rated Voltage | 115 VAC |

| Motor Dimension | 72mm |

| Protection Type | IP55 |

| Insulation Class | Class B |

| Transport Package | Standard Exporting Package |

| Specification | 240*240*240mm |

| Trademark | PBM |

| Origin | Suzhou, Jiangsu |

| HS Code | 8414599050 |

| Production Capacity | 50, 000PCS/Year |

Product Description

China Supplier Waterproof 115V EC 250mm Commercial Ventilation Fan for FFU

Model No.: PA3N250B1E-SZ0

1.General Characters

Model | PA3N250B1E-SZ0 |

Rated Voltage | 115 VAC |

Operating Voltage | 92~134 VAC |

Rated Speed | 3000 RPM |

Input Current | 1.8 A |

Input Power | 120 W |

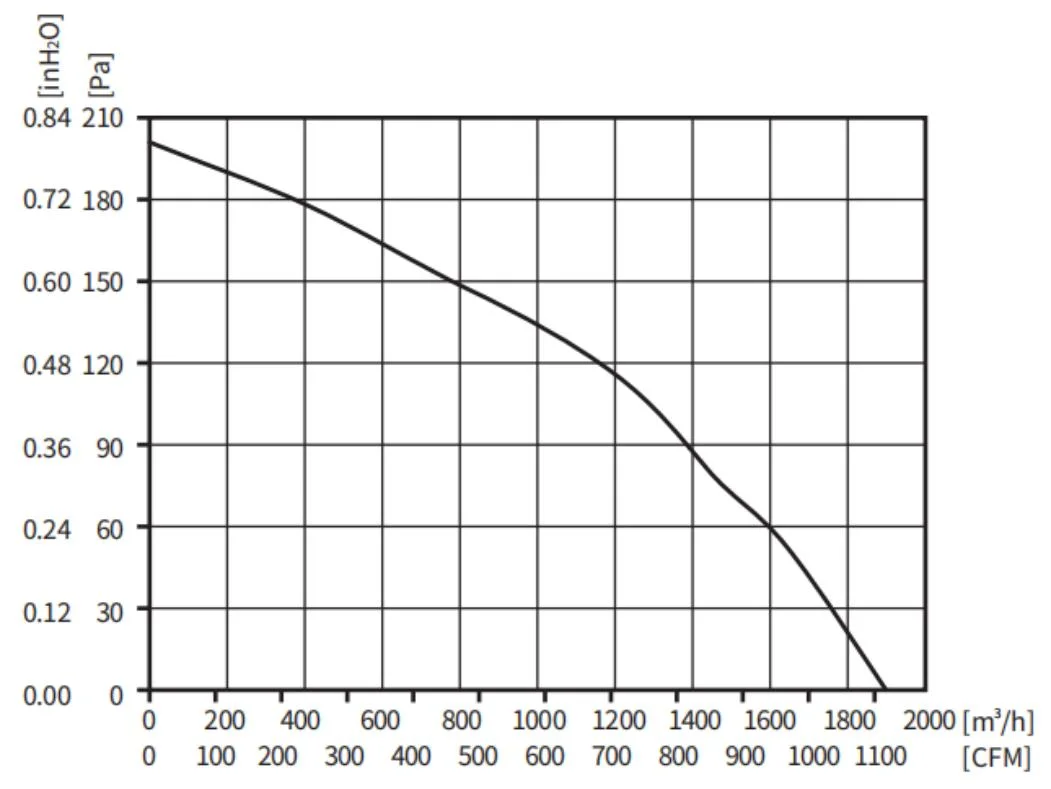

Air Flow | 1900 m3/H |

Static Pressure | 200 Pa |

Sound Level | 63 dB(A) |

Protection Type | IP55 |

2.Mechanical Characters

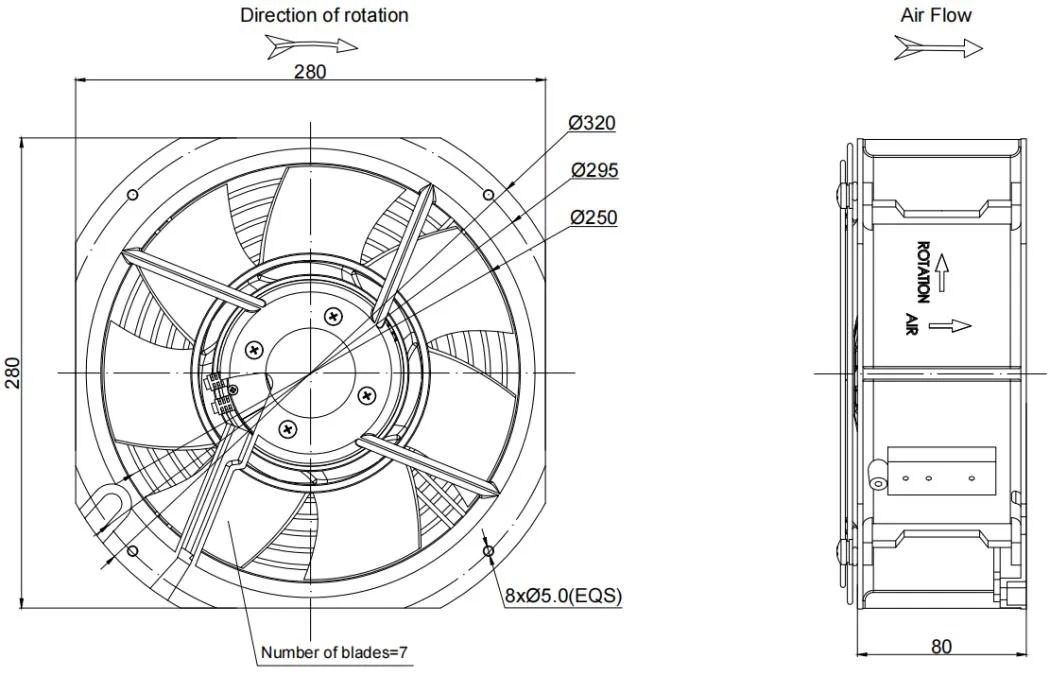

Dimension | 280mm X 280mm X 80mm (see dimension drawing) |

Material of Impeller | PA66+25%GF |

Mounting Position | Any |

Surface of Rotor | Coated in black |

Bearing System | NMB ball bearing |

Lead Wire | D1 |

Weight | 1860g |

Package | Standard |

3.Environmental Characters

Locked-rotor Protection | Over-current limiting circuit protects motor from damage at least for 72 hours of locked rotor condition at rated voltage. |

| Maximum Current under Locked Rotor | A, Typical inrush current when the motor is trying to re-start under locked rotor conditions is 2~4 times the normal running |

Reverse Polarity Protection | No damage if the positive and negative leads are reversed under maximum operation voltage conditions. |

Over Voltage Protection | The circuit will be shut down automaticlly when input voltage over threshold. And re-started when Voltage down to threshold below. |

Soft Start | In 5 seconds after power on and speed control voltage gets to 1.5V or PWM duty cycle at 10% above. |

Related Products

IP55 Fan Ec-AC Axial Fan Fan Ec-AC Axial Fan Forward Curved Centrifugal Fan Blower Fan with 146mm Impeller

FOB Price:US $51.4-57.4/Piece FOB Price:US $40.7-45.5/Piece FOB Price:US $51.2-57.2/Piece FOB Price:US $52-58/Piece Contact Now Contact Now Contact Now Contact Now

Fan Ec-AC Backward Cur... Air Blower Fan Centrifugal Fan for HVAC Curved Centrifugal Fan

FOB Price:US $53.1-59.3/Piece FOB Price:US $49-56/Piece FOB Price:US $45.2-48.88/Piece FOB Price:US $73.95-75.78/Piece Contact Now Contact Now Contact Now Contact Now

Certificate Show:UL / CE / Rohs

Application Scopes:Ventilation & Purification / Air Conditioning / Refrigeration / IT & Electronic Industry / Medical Industry / Heating / Automotive Industry / Household Electric Appliances / Cloud Date Center / Mechanical Equipment and Systems.About PBM:High Quality EC Fan / Competitive Price / Strong Team / Long Life Expectance / Fast Delivery / Customization Available / Attentive Service / Professional AssistanceLaboratory / Packing Method / Workshop / Warehouse

FAQ

Frequently Asked Question

Q: What are electronically commutated motors?

Electronically Commutated motors are brushless DC motors where the direction of the electric current is switched using electronic controllers. As the switching of the current is technically known as 'commutating', brushless motors are also called 'electronically commutated' motors. EC motors provide the advantages of brushed DC motors in terms of the ability to have variable speed control, but without the drawbacks of brushes.

Q: What are the advantages of EC motors?

EC motors are very high efficiency electric motors (80%) and maintain a high efficiency level at part speed. This means that in most cases they use less than one third to half of the electricity used by traditional induction motors, which in turn translates into lower operating costs and short payback periods. As EC motors have a higher efficiency this ensures that the motors run cooler in application which ensures a longer life for the motor.

In terms of speed control and features, because the motor's operation is controlled by software, EC motors allow customers to optimize and integrate the motor, fan and controller with the application, and to include features like data communications, constant volume control, variable speed.

Features & Advantages

Q: What about cost?

The initial outlay for an EC motor is more expensive than the traditional induction / shaded pole motors and this is mainly due to the electronic components required to drive the commutation. In recent years the cost of electronic components has reduced dramatically as volumes increase.

The huge energy savings provided by EC motors, mean equally large savings in operating costs, which in turn translate in payback periods as short as a few months combined with a longer life expectancy.

In our case, together with high energy savings, low use of raw material, low part count and simple electronics, have allowed us to make our motor price very competitive.

Q: How are EC motors 'sustainable'?

The huge energy savings provided by our EC motors directly translate into large carbon emissions savings.

By using an EC motors in your application we are able to assist our customers in dramatically reducing the air pollution (CO2) generated by their applications. This is due to the motors high efficency & low energy costs which helps to preserve the world for a 'greener' future.

EC Motors are designed & manufactured using 70% less copper and 80% less steel than traditional induction and shaded pole motors which has a dramatic reduction in environmental impact in producing these raw material components.

services to the clients.Contact UsWe highly appreciate your any enquiry by email, call or instant message.

Prev: Industrial Drum Fan 16 Inch High Velocity Metal Electric OEM Commercial Floor Ventilation Fans

Next: Silicone Ketchin Ware Kitchenware Kitchen Accessories Set Kitchen Utensil

Our Contact